The advancements in manufacturing over the years have been nothing short of remarkable. With each new advance, factories and manufacturers can operate more efficiently and produce products at a lower cost. This is why automation in manufacturing is always welcome.

Automation helps reduce the number of errors made in the manufacturing process, leading to higher quality products. In addition, automation helps to speed up the manufacturing process, leading to increased production and reduced costs.

Many statistics support the value of automation in manufacturing. For example, a study by The Manufacturing Institute found that 88% of manufacturers who had implemented or planned to implement automation cited increased efficiency as the primary benefit. Another study by Boston Consulting Group found that for every $1 spent on robotics, companies saw a return on investment of $2.36.

Automation is integral to modern manufacturing, and its advancements are always welcome. With its ability to increase efficiency and quality while reducing costs, automation is critical in keeping our factories and manufacturers competitive in the global economy. However, you might not know where to start. Here are a few automation procedures to consider.

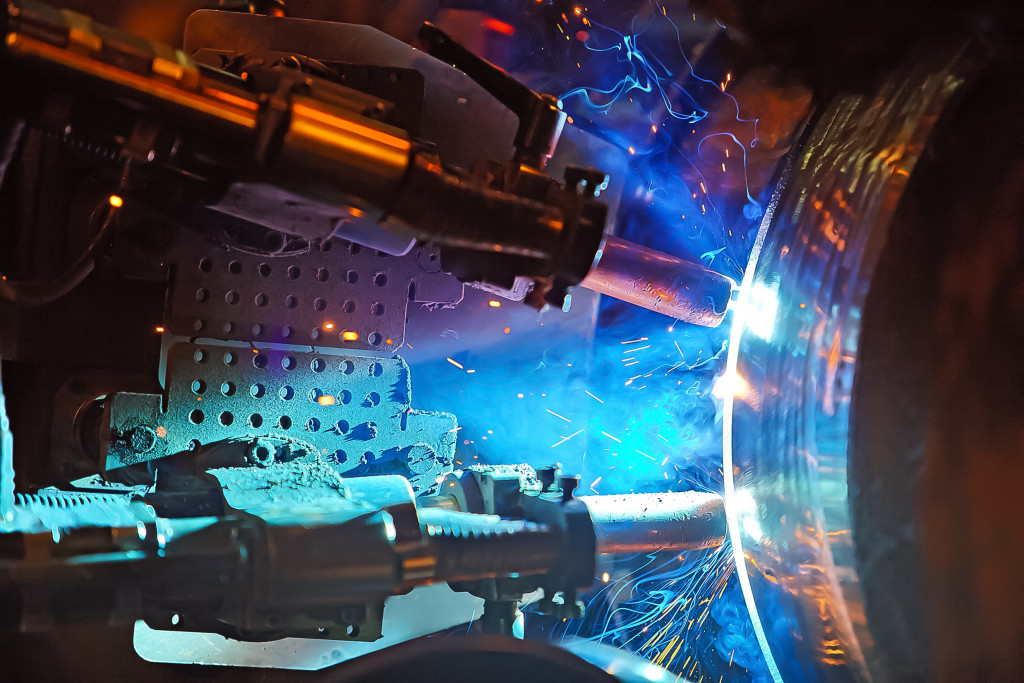

Welding

Welding is an essential process for manufacturing. It helps to join two or more metal parts and can be used on various materials, including steel, aluminum, and titanium. In addition, welding produces very little waste compared to other manufacturing processes, and it is a very versatile process that can be used in many different applications.

Welding has come a long way in recent years. Modern welding equipment is reliable and efficient, making it the perfect choice for manufacturing companies looking to increase their production output. In addition, welders are in high demand and can often command high wages. This makes welding an attractive option for companies looking to improve their bottom line.

Welding is a critical part of modern manufacturing, and its advancements are always welcome. With its ability to join metals together quickly and efficiently while producing very little waste, welding is perfect for companies looking to increase their production output. Robotic arms controlled by programmed electric motor gearboxes can be used to automate the welding process. This eliminates the need for human operators, leading to increased efficiency and reduced costs.

CNC Machining

CNC machining is a process that uses computer-controlled machine tools to remove material from a workpiece. This process is perfect for manufacturing companies looking to produce high-quality parts. In addition, CNC machining can be used on various materials, making it a versatile option for many applications.

CNC machining requires a pre-programmed design from which the machine tool will follow. This design can be created using a computer-aided (CAD) program or a three-dimensional (3D) model. Once the design is complete, it is transferred to the machine tool, and the machining process begins.

The advantages of CNC machining are many:

- It is a very accurate process that can produce parts with tight tolerances.

- CNC machining is versatile and can be used on various materials.

- CNC machining is fast and efficient, making it perfect for companies looking to increase their production output.

- CNC machining produces very little waste, making it an environmentally friendly option.

Conveyor Systems

Conveyor systems are an integral part of many manufacturing operations. They are used to move materials from one location to another, and they can be used to transport finished products or raw materials. Conveyor systems come in various sizes and can be customized to meet the specific needs of a manufacturing operation.

Conveyor systems offer many advantages over other methods of material handling:

- They are very versatile and can be used in various applications.

- Conveyor systems are fast and efficient, making them perfect for companies looking to increase their production output.

- Conveyor systems are safe and reliable, making them an ideal choice for companies looking to improve worker safety.

- Conveyor systems are easy to maintain and can be customized to meet the specific needs of a manufacturing operation.

Packaging Automation

Packaging automation is a process that uses machinery and equipment to automate the packaging of products. This process is perfect for companies looking to improve their production output and efficiency. In addition, packaging automation can help to reduce labor costs and enhance the quality of products.

Packaging automation comes in various forms, from simple machines that seal and label products to more complex systems that can handle multiple products simultaneously. In addition, you can customize packaging automation to meet the specific needs of a manufacturing operation.

The advantages of packaging automation are many:

- It is a speedy and efficient process that can help to increase production output.

- Packaging automation can help to reduce labor costs by automating repetitive tasks.

- Packaging automation can improve product quality.

- Packaging automation is safe and reliable, making it an ideal choice for companies looking to improve worker safety.

Final Thoughts

Automation will always be advantageous for any manufacturing company, whether for welding, machining, conveyor systems, or packaging. With its many benefits, automation is worth the investment for any company looking to improve its production output and efficiency.