Laser cutting has grown to be the go-to technology in most markets. But, this technology comes in various sizes, types, and complexity depending on the application in question. So, while you may be planning to buy your next laser cutting equipment, remember that and that how well you source these solutions will determine the success of your projects.

That aside, several factors play a crucial role in dictating the choice of laser cutting and engraving machines for sale for different applications. Typically, these revolve around the materials that you are working on; but, more to that, consider the following:

Modes of Applications

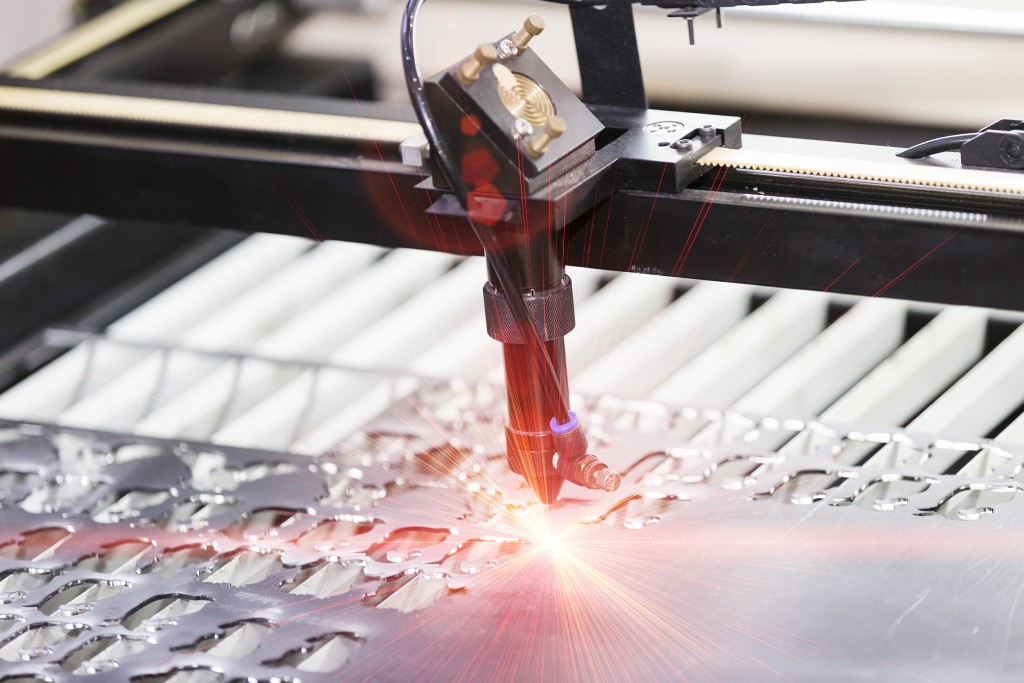

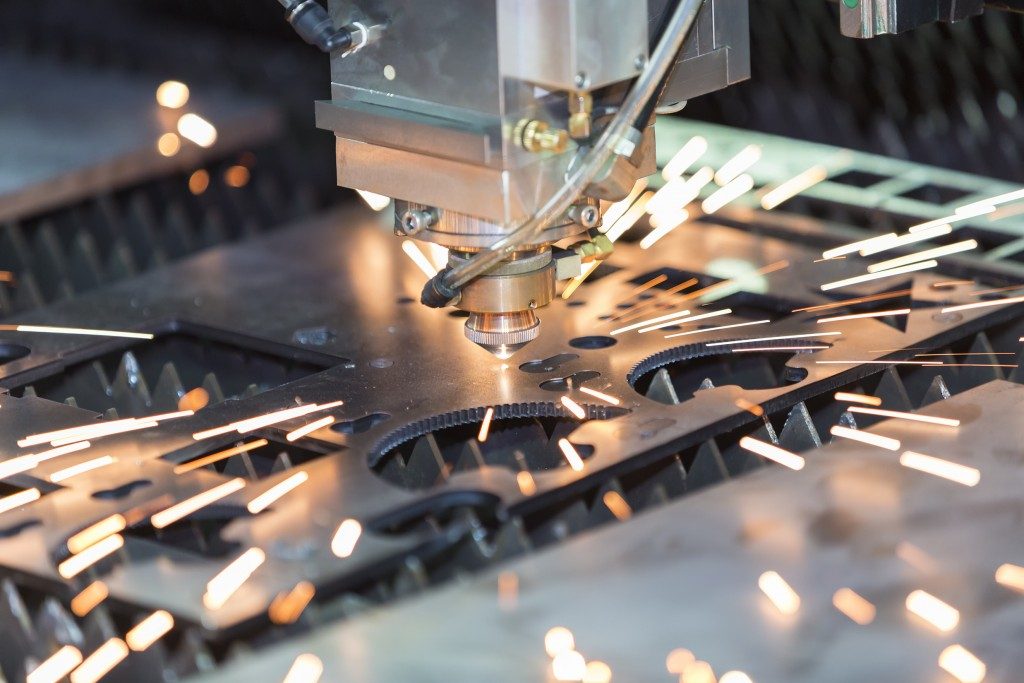

Cutting – This is the most common application for which most markets use laser technology. That is because laser machines cut materials to produce some of the cleanest edges. That has helped reduce the cost of investing in finishing equipment to file the edges.

Shaping – You can use laser technology to create 2D curves around the material that you are on. Again, thanks to the clean edges that this technology produces, you will save the time you would have otherwise spent on other machining processes such as chamfering, deburring and beveling, on the curved edges. Oh, and note the differences on that to better understand the orders your clients could place.

Sculpting – This application is more about creating three-dimensional objects with your laser equipment. Be careful to specify this when placing your order for laser equipment. You also may prefer a buying hybrid laser equipment if you need one that can handle both 2D and 3D operations.

Engraving – This is a unique laser shaping procedure. For this, you will work directly on the surface of your work, be it wood or stone. Unlike cutting and shaping, which cut all through the material you are working on, engraving limits the process to a certain depth. But still, you can specify whether most of your projects require deep or shallow engraving.

Types of materials

Talking of materials, it is highly recommendable that you buy a laser machine that can work on your materials without burning out or inflicting burns on the material. Typically, you can use a wood laser machine for engraving, shaping, cutting or sculpting other soft materials such as bricks and tombstones. But, for harder materials, such as granite, you may require a laser machine that is specific for that material. You, however, can request your laser equipment supplier to recommend one that can work on different materials. While such may be costlier than single-mode laser equipment, its features will help you change the operation as you transition between soft and hard materials.

Not every laser equipment in the market will be appropriate to use in your case. Some will be larger while others will be so simple that they cannot help you minimize production costs or reduce production time. So, be careful when choosing yours. If you still do not know where to start with that or whether to go for that laser cutting and engraving machines for sale, ask. Your laser equipment supplier will advise you on the options to meet your laser cutting or engraving needs satisfactorily.